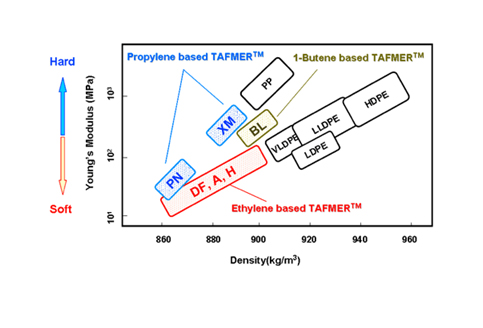

Low-crystallinity copolymer modifies polyethylene (PE) and polypropylene (PP) offering softness, improved impact resistance and lower melting point.

The TAFMER™ family of polyolefin elastomers is comprised of versatile copolymers that offer chemists and engineers more freedom to tailor polyethylene, polypropylene, EPDM, and polyamide compounds with unique properties. Owing to its low density, TAFMER™ is preferred by compounders who need to formulate the lowest cost solution for their customers. TAFMER™ is widely used in automotive thermoplastic polyolefin (TPO) compounds, wire & cable materials and packaging applications.

The polymer backbone of TAFMER™ is polyolefin based. Many grades are FDA compliant, and are supplied in talc-free form for immediate use in packaging film intended for food or aqueous containment. TAFMER™ is considered a most versatile polyolefin elastomer by formulators who are able to select the precise physical property balance they need, from a full menu of copolymers.

Olefinic Copolymers

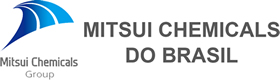

The TAFMER™ product family includes:

| TAFMER™ A, DF | Ethylene- Butene copolymers | TAFMER™ A offers “fish eye” and heat seal initiation temperature (HSIT) control in transparent films. TAFMER™ DF offers excellent value in use. |

|---|---|---|

| TAFMER™ BL | Butene-Ethylene and Butene-Propylene copolymers | TAFMER™ BL offers peal strength control in packaging applications. TAFMER BL2400 Series offers low HSIT in PP films. |

| TAFMER™ H | Ethylene-Octene copolymer | TAFMER™ H offers higer tensile strength over TAFMER™ DF |

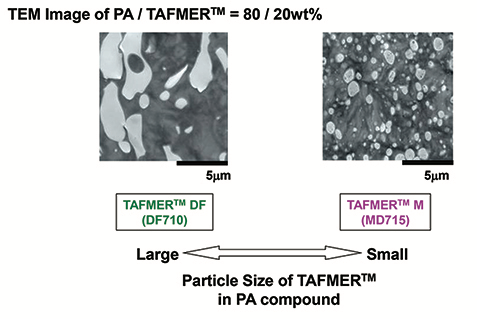

| TAFMER™ M | Acid Modified TAFMER™ | TAFMER™ M offers utility as a low cost impact modifier for polyamides. |

| TAFMER™ P | Ethylene-Propylene copolymer | TAFMER™ P offers improved clarity in polyethylene films vs. TAFMER™A or DF. |

| TAFMER™ PN | Propylene based Elastomer with nano-crystal structure | TAFMER™ PN offers improved clarity and impact resistance in polypropylene applications. |

| TAFMER™ XM | Propylene-Butene copolymer | TAFMER™ XM offers an outstanding balance of HSIT and coefficient of friction (COF) for polypropylene sealant applications. |

New Innovative TAFMER™

An exciting innovation, TAFMER™ M is an acid modified elastomer. TAFMER™ M may be used to modify engineering plastics. As a function of pressure, heat and time, acid modified TAFMER™ M reacts with polymers that contain a RCONR2 amide functional group, a ROH hydroxyl functional group, or a RCOOR’ ester functional group, to improve room temperature and low temperature impact resistance when blending, or bonding to plastics containing these functional groups.

TAFMER™ PN offers a unique balance of softness and the heat resistance. TAFMER™ PN is a propylene based elastomer with controlled nano crystalline elements that add remarkable high heat resistance to this very soft material. The crystalline elements are finely dispersed in an amorphous matrix, which ensures excellent transparency. TAFMER™ PN offers Shore A 70-84 and a melting point of 140 to 160°C.

TAFMER™PN has superior elasticity when compared to ethylene based elastomers.

TAFMER™PN will not snap even when lifting a 500 gram weight in water boiling at 100℃.

TAFMER™PN does not whiten even when bent.

Related Products

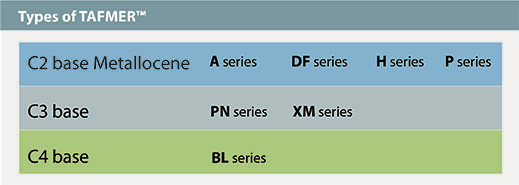

TAFMER™ polyolefin elastomer is a low-crystallinity alpha-olefin copolymer that features softness, low melting point, and compatibility with polyethylene (PE) and polypropylene (PP). When TAFMER™ is used to modify either PE or PP, the degree of compatibility may be selected to tailor the morphology of the compound. The resultant shift in physical properties is engineered to meet the requirements of the application.

Polyethylene Modification

Specific grades of TAFMER™ provide varying levels of compatibility in PE. The morphology of the polyethylene compound dictates its physical properties, and may be tailored to meet the needs of your specific application.

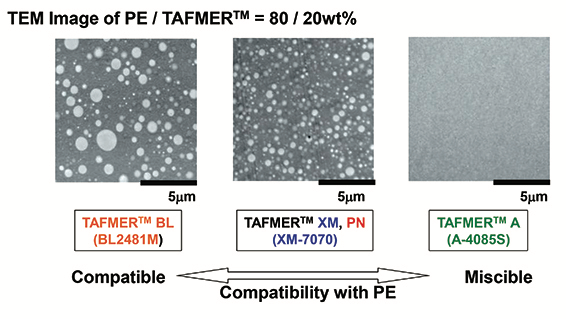

Polypropylene Modification

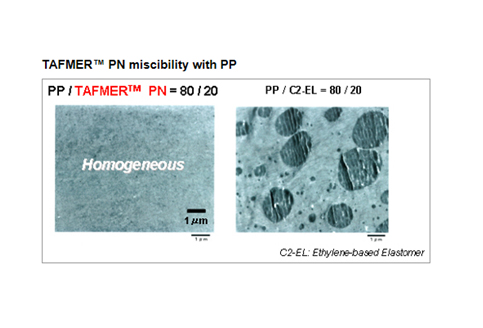

TAFMER™ grades offer varying levels of compatibility in PP. The morphology of the polypropylene compound dictates its physical properties, and may be tailored to meet the needs of your specific application.

TAFMER™ miscibility in Polypropylene (PP)

TAFMER™ XM is highly miscible in PP. In packaging film applications, the benefits of enhancing PP with TAFMER™ are:

- Lower Heat Seal Initiation Temperature (HSIT)

- Film Transparency

- Outstanding balance of HSIT and COF

TAFMER™ PN is a newly launched series with finely dispersed crystalline structures in an amorphous matrix. The crystalline structures provide remarkably high heat resistance, yet the material retains outstanding softness. Because these crystalline structures are finely dispersed in an amorphous matrix, TAFMER™ PN offers excellent transparency and reduced stress whitening of polypropylene film.

In Wire & Cable applications, the miscibility TAFMER™ allows it to function as plasticizer of polypropylene, without sacrificing scratch and abrasion resistance.

In general injection molding applications, the miscibility TAFMER™ PN in PP offer a great advantage in applications requiring both transparency and impact resistance. In addition, PP modified with TAFMER™ PN exhibits improved hinge strength and reduced stress whitening.

Polyamide (“nylon”) Modification

TAFMER™ M offers cost effective impact modification of polyamide “nylon” resins.

When used as a resin modifier, TAFMER™ dramatically improves the performance of PE, PP, and other thermoplastics in automotive, wire and cable, as well as packaging applications.

TAFMER™ Polyolefin Elastomer Applications

TAFMER™ is widely used in automotive, industrial, and packaging applications, and may be processed by:

- Cast and Blown Film Extrusion

- Extrusion Coating

- Pipe Extrusion

- Injection Molding

- Foam and Calendering

Automotive Applications

The TAFMER™ A, DF, and P series of ethylene based copolymers are used to enhance polypropylene (PP), for injection molded automotive parts including bumpers, instrument panels, and trims. As a component of a thermoplastic olefin (TPO) compound, TAFMER™ offers:

- Improved Cold Temperature Impact Resistance and Ductility

- Controlled Gloss and Paintability

- Sustained Resistance to Heat Degradation and Weathering

Packaging Applications

TAFMER™ enables the film engineer or package designer to:

- Adjust Easy-Peel Properties

- Maximize Impact Resistance

- Optimize Heat Seal Properties and Retain Transparency

- Control Shrink Properties and Self-Adhesiveness

- Minimize Stress Whitening

Polyethylene Modification

The TAFMER™ A and M series of ethylene based copolymers are used to enhance the properties of polyethylene (PE) for cast films, blown films, as well as extrusion coating.

| Process | Enhanced Properties | TAFMER™ Series | Technical Information |

|---|---|---|---|

| Blown Film | Heal Seal and Transparency | A | Heat Seal & Transparency |

| Extrusion Coating | Polypropylene Adhesion | A | PP Adhesion |

| Blown Film & Cast Film | Cling, Transparency, Elongation | A | Cling, Elongation & Transparency Properties |

| Extrusion Coating | Metal Adhesion | M | Metal Adhesion |

Polpropylene Modification

TAFMER™ XM and PN series propylene based copolymers, as well as TAFMER™A series of ethylene based copolymers, are used to enhance the properties of polypropylene (PP) for cast film and biaxially oriented film (BOPP).

| Process | Enhanced Properties | TAFMER™ Series | Technical Information |

|---|---|---|---|

| Cast Film | Easy-Peel, Impact Resistance, Heat Seal | A | High Retort CPP Easy Peel |

| Blown Film, BOPP | Heal Seal, Transparency, Shrink | XM | BOPP XM |

| Blown Film & Cast Film | Self-Adhesiveness (Protective Film) Anti-Stress Whitening (Decorative Film) |

PN | Not available |

Wire & Cable Applications

TAFMER™ DF and M series of ethylene based copolymers are used to modify ethyl-vinyl acetate (EVA) for wire coating applications.

| Process | Enhanced Properties | TAFMER™ Series | Technical Information |

|---|---|---|---|

| Wire Coating | Flexibility, Elongation, Scratch Resistance | DF, M | EVA Modification Wire Coating |

TAFMER™ XM series are propylene based copolymers are used to modify polypropylene (PP) for wire coating applications.

| Process | Enhanced Properties | TAFMER™ Series | Technical Information |

|---|---|---|---|

| Wire Coating | Balance of Flexibility / Abrasion Resistance | XM | Propylene Based Wire Cable XM |

Contact Us

MITSUI CHEMICALS DO BRASIL